Toggle Navigation

- Home

- About Us

- Products

- Titanium and Titanium Alloys

- Zirconium and Zirconium Alloys

- Zirconium and Zirconium Alloys Tube and Pipe

- Zirconium and Zirconium Alloys Bar and Rod

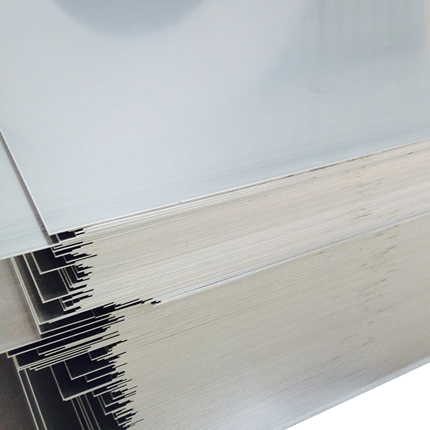

- Zirconium and Zirconium Alloys Sheet and Plate

- Zirconium and Zirconium Alloys Wire

- Zirconium and Zirconium Alloys Fasteners

- Zirconium and Zirconium Alloys Foil

- Zirconium and Zirconium Alloys Forging

- Zirconium and Zirconium Alloys Pipe fittings

- Zirconium and Zirconium Alloys Equipment

- Tantalum and Tantalum Alloys

- Niobium and Niobium Alloys

- Molybdenum and Molybdenum alloys

- Magnesium and magnesium alloys

- Copper and copper alloys

- Aluminum and aluminum alloys

- Tungsten and tungsten alloys

- Power electronics

- Semiconductor material

- Carbon fiber material

- Optical material

- Other new materials

- News

- Service

- Download

- Feedback

- Contact Us