Standard Modulus Carbon Fiber Tubing (SM)

This is the most common grade of carbon fiber used for our carbon fiber tubes. Standard modulus offers excellent strength and stiffness. It is 1.5X stiffer than aluminum and is the most economical grade.

Intermediate Modulus Carbon Fiber Tubing (IM)

This grade of tubing offers enhanced stiffness over standard modulus carbon fiber tubing with the same or better strength. Intermediate modulus is approximately two times stiffer than aluminum tubing.

High Modulus Carbon Fiber Tubing (HM)

At three times stiffer than aluminum (or equivalent to steel stiffness), this grade of tubing has very similar strength to standard modulus carbon fiber tubing. It is an excellent choice for demanding, weight sensitive applications.

Ultra-High Modulus Carbon Fiber Tubing (UHM)

Incredible stiffness at four-five times that of aluminum or 1.5 times that of steel. Ultra-high modulus has lower strength and is not recommended for high stress applications.

Standard Carbon Fiber Tube Options

Carbon fiber tubes can be fabricated into virtually any shape. These include:

Round

Square

Rectangle

Oval, elliptical

Octagon, hexagon

Custom shapes and profiles;

Diameters

We offer stock, build-to-order, and custom carbon fiber tubes in multiple diameters. Custom tooling can be made to order for reasonable cost. See our current Mandrel List.

Wide range of diameters from 0.060” to over 10”

Most common fractional sizes (ID and OD)

Tapered diameters

Many metric sizes

OD grinding add-on service (+/-0.0005”)

Wall Thickness

Carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. Virtually any wall thickness can be made by changing the number of layers or combining different prepreg thicknesses (0.003” – 0.010”).

Common tube thicknesses include:

Thin wall: 0.010”, 0.020”

0.035”, 0.041”, 0.058”, 0.064”, 0.092”

1/8”, 1/4” or thicker

Length

Roll-wrapped carbon fiber tubing is sold in standard lengths or can be built custom to reduce waste.

Maximum length is 100” (for most ID sizes)

Long lengths: tubes can be joined together with internal (or external) ferrules to achieve the required length.

One-piece longer lengths are possible for larger orders

Tubes can be cut to size for an additional charge.

Precision cutting tolerances available (+/-0.010” or better)

Exterior Finishing

Carbon fiber tubes can be made with a variety of exterior finishes. Our standard finishes include:

Cello-wrap (glossy with resin ridges – natural result from production process)

Matte (sanded or centerless ground)

Satin (sanded, high grit)

Glossy (clearcoat)

Painted

Visit our finishing capabilities page to learn more.

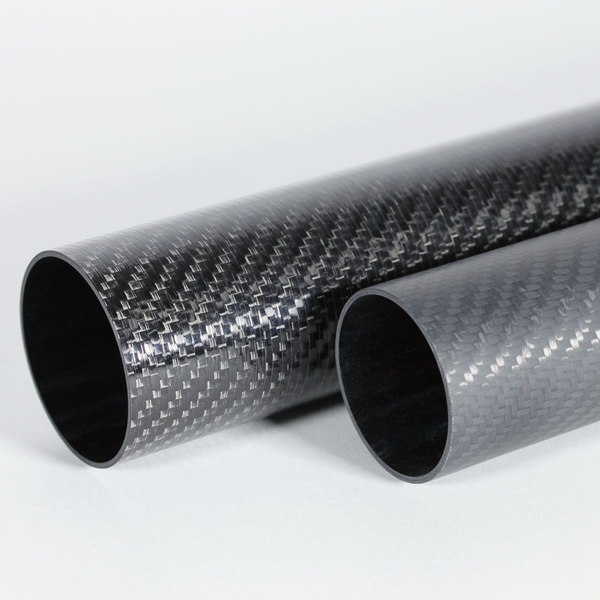

Exterior Materials

We offer many standard exterior materials for our roll-wrapped carbon fiber tubes. These include:

2×2 twill fabric

Plain weave fabric

UD (unidirectional)

Silver texalium

Red/black

Blue/black

Custom colors/styles: any fabric that is commercially available can be utilized to make carbon fiber tubing.

Custom-Made Carbon Fiber Tubes

When a job calls for a custom-made carbon fiber tubing, turn to Clearwater Composites. We have the capacity to create carbon fiber and composite materials in any shape or size, and we work closely with our clients to meet their exact specifications.

If you can’t find what you need in our extensive product inventory, talk to one of our engineers about your specific needs.